Based on the previous introduction to bulletproof vests. I believe everyone has a certain understanding of the functions, appearance, and how to choose bulletproof vests.

Today we- China Xinxing Guangzhou Imp&Exp Co., Ltd. will introduce the components of bulletproof vests. Let everyone have a deeper understanding of bulletproof vests.

Material.

As we know, There are currently only two types of bulletproof products - PE and aramid. Same to the bulletproof vest. The beginning of manufacturing bulletproof vests is to cut the outline of the vest on the woven fabric(UD fabric). Used to create bulletproof panels. It is usually cut according to the size of the protective area of the bulletproof vest.

UD fabric(PE or Aramid). This fabric also we can sell.

2. Bulletproof panel

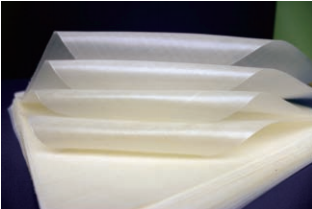

After cutting is completed. We will get many pieces of fabric cut according to the size of the bulletproof vest. At this point, we need to stack them all up. Like this:

It is necessary to determine how many layers of fabric a panel needs based on the protection level and material composition. For example, If the PE UD fabric areal density is 160g/m2 so NIJ IIIA 9mm need 22 layers and NIJ IIIA.44 need 30 layers.

After all are neatly stacked. Putting on a coat will turn it into a bulletproof panel.

3. Put into the jacket.

The lining is completed. We need to put him in the coat. The jacket has become bulletproof due to the addition of the bulletproof panel. At this point, a bulletproof vest was born.

The above is the general production process and components of a bulletproof vest. If you are interested in these products, please do not hesitate to contact us: [email protected]